"Deploying technology that makes 'Power without Pollution' a reality."

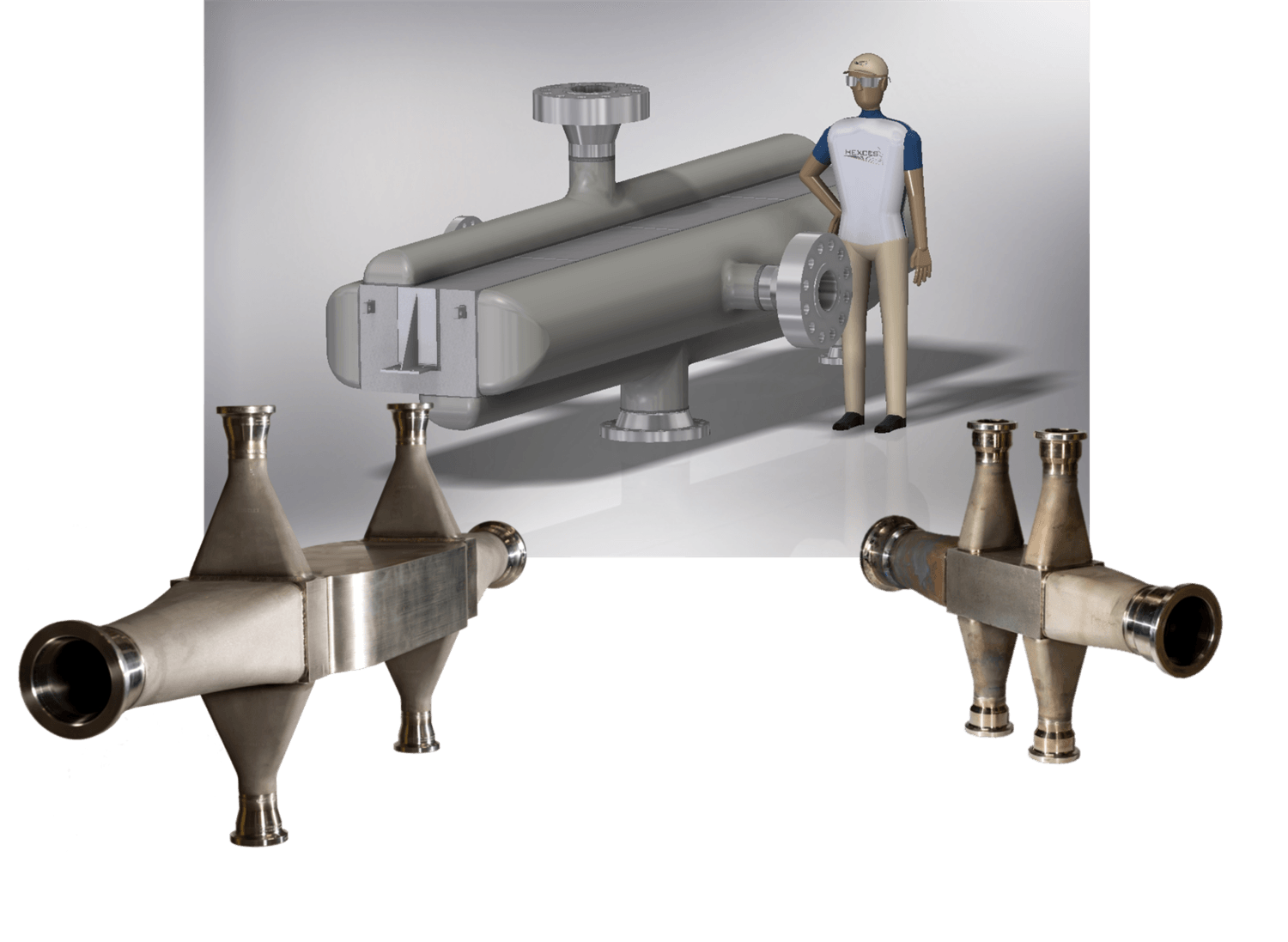

HEAT EXCHANGERS

Clean Energy Systems, Inc. has opened a new division named HEXCES to focus on the design, development, manufacture, and service of compact platelet heat exchangers (CPHXs). Also known as printed circuit heat exchangers (PCHEs), these devices are known for their high pressure capability, increased effectiveness, and compact size and footprint. The unique capabilities of CPHXs provide efficient thermal management solutions across a variety of market applications including power generation, off-shore oil and gas, aerospace, and cryogenic and chemical processing.

For more information, please visit www.hexces.com.

Benefits Of Compact Platelet Heat Exchangers (CPHXs)

- Four to six times smaller and lighter than conventional designs such as shell-and-tube exchangers

- Reduced weight, footprint, and supporting structures allows for flexibility in deployment location, shipping, and plant layout

- Unmatched surface area per unit volume of the exchanger

- Reduced energy requirement and cost due to high thermal effectiveness

- Exceptionally high heat transfer coefficients achievable with small-hydraulic diameter flow passages

- Extremely low fluid inventory

- High pressure capability, in excess of 600 bar

- Wide operating temperature range from -200 to 900˚C

- Improved process design, plant layout, and processing conditions

- Can be used for gases, liquids, and/or two-phase flows

- Channels can be optimized for counter, co-, or cross flow

- Multiple fluid streams possible

- No inter-plate/inter-channel seals or gaskets required

- Inherent structural design eliminates catastrophic failure modes

- Significantly reduces vibration/cyclic failure modes

- Wide range of materials of construction possible including stainless steel, nickel and cobalt based alloys, copper, titanium, and more

- Combination of multiple materials possible