"The Power to Reverse Climate Change"

CARBON-NEGATIVE ENERGY (CNE)

To change our generation’s legacy and reverse climate change; CNE is on the cutting edge of an industry revolution.

More than 180 nations set the goal of limiting global temperature increase to 1.5 °C, compared to pre-industrial levels. In order to meet this goal, the Intergovernmental Panel on Climate Change (IPCC) has reported the deployment of large scale “carbon-negative” cycles are needed by 2040. Biomass processes that include carbon removal and storage (also known as "BiCRS") have the potential to remove significant amounts of the greenhouse gas (GHG) carbon dioxide (CO2) from the atmosphere. They combine natural, organic plant materials with technology for carbon capture and long-term storage. Some BiCRS processes can also produce renewable fuels and/or electricity.

CES' oxy-combustion technology offers a carbon-negative energy (CNE) solution that is both technologically feasible and economically viable. The systems use proven and reliable aerospace technology to produce clean power, water, and nearly pure CO2 that is easily captured for safe and permanent storage. When using a waste biomass fuel that consumes carbon over its lifetime and capturing and permanently storing the produced CO2, the process results in net negative carbon emissions, essentially scrubbing the harmful greenhouse gas from the atmosphere. This carbon dioxide removal (CDR) process can also produce renewable fuels such as hydrogen.

The California market offers a unique opportunity for CES’ CNE plants. Due to the severe drought conditions that California has experience over last several years, and numerous traditional biomass power plants closing around the state, there is an excess of forestry and agricultural waste. Biomass plant closures have left farmers with few choices to dispose of their waste and have increased the number of open field agricultural burns, further exacerbating the poor air quality in the state's Central Valley. Deployment of CES’ CNE plants provides a mechanism for simultaneously solving multiple challenges plaguing our state by providing responsible disposal for the abundance of wood waste while improving the Valley’s air quality and supporting the State’s ambitious goals to reduce GHG emissions (recent state mandate requires 100% carbon-free electricity by 2045).

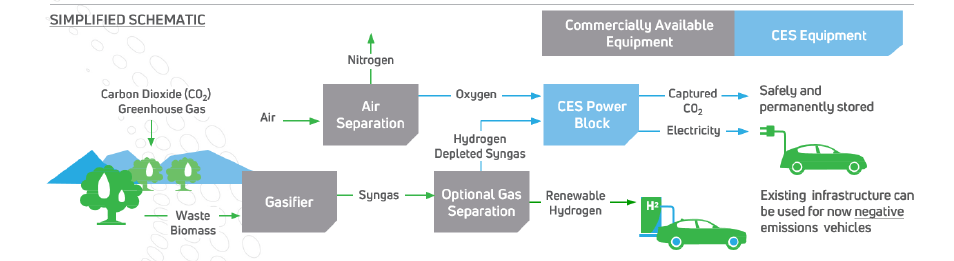

A recent study has found that commercial deployment of CNE plants can support California’s agricultural, energy, and transportation sectors. Below is a simplified schematic showing how the plants can use waste biomass to produce renewable electricity or renewable hydrogen (RH2), or a combination, that can feed into the State’s existing infrastructure. CES is developing our first commercial CNE project at an existing biomass facility in California’s Central Valley, with operations expected to begin in late 2025. Though modest in size, the plant will be capable of removing 6 million tons of CO2 over its lifetime while providing renewable fuel to the State’s transportation market. Click for more information on CES BiCRS and our plan to deploy a fleet of carbon-negative energy plants across California.

CARBON NEGATIVE ENERGY | HOW IT WORKS

CES Carbon Negative Energy (CNE) plants use waste biomass fuels that are gasified to produce a synthesis gas. This “syngas” can then be separated to produce renewable hydrogen (RH2) or directly fed to the power block. Nearly pure oxygen is generated by an air separation system and used by CES‘ proprietary technology with the bio-syngas to produce electricity to power the plant and electric vehicles. Greater than 99% of the carbon from the process is captured for permanent storage. By using fuel that consumes carbon dioxide (CO2) over its lifetime and safely and permanently storing captured CO2, the process results in net-negative carbon emissions, effectively removing the greenhouse gas from the atmosphere.